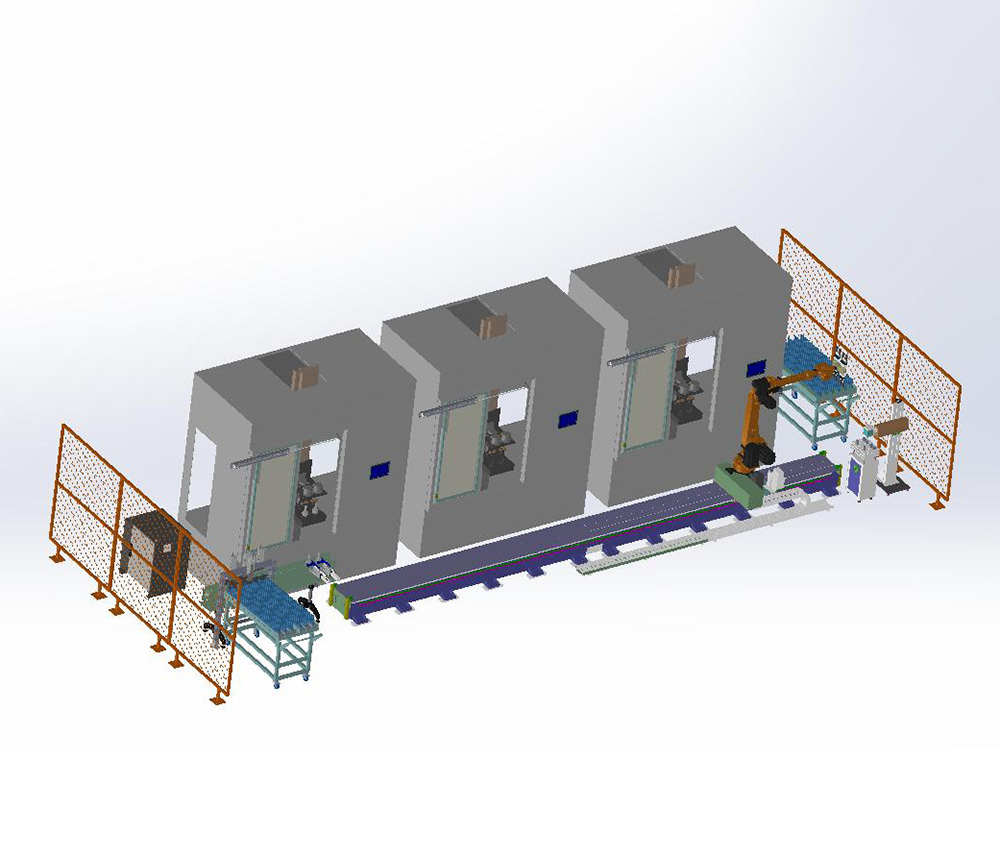

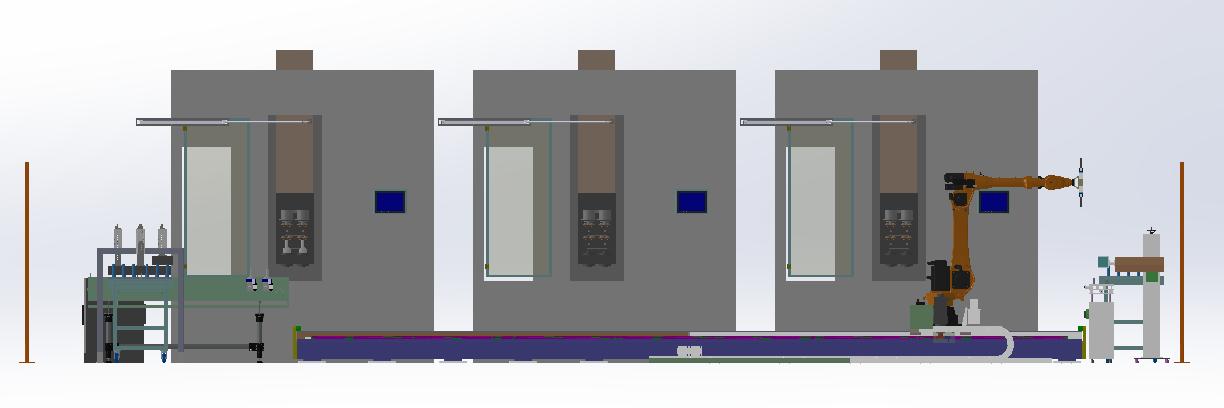

Location:Home / Product / Automation / Induction heating robotic arm automatic line

| Product Name | Induction heating robot production line | |

| Input power | Input maximum power | 60-400KW |

| Input maximum current | 90A--600A | |

| Input voltage and frequency range | 360~400Vac 50/60Hz | |

| Operating frequency range | 400k~15kHz | |

| cooling water | water pressure | 0.1-0.6 MPa |

| flow | 50~200L/minute | |

| heating mode | heat | Intermittent or continuous heating |

| Temperature control mode | Constant energy, constant power or infrared temperature control | |

| control model | PLC program control | |

| environment | Operating temperature | 0 ~ +45 °C |

| storage temperature | -25 ~ +70 °C | |

| relative humidity | 0~95%(No condensation) | |

| induction heating equipment | Heating power supply | 50--360KW induction heating equipment |

| induction coil | Purple copper, 3D printing, engraving+brazing | |

| Power supply and transformer | Split type, integrated type | |

| manipulator | brand | Yaskawa, Kuka, etc |

| model | Select according to design | |

| Ground track | Determine based on design | |

| clamp | Based on product design | |

| Front and rear ends | front end | Determine as needed |

| rear-end | Testing, marking, etc | |

| Weight and dimensions | size | be pending |

| weight | 2000-5000KG | |

| Scope and rhythm of application | Application scope | Suitable for automatic high-frequency brazing, high-frequency quenching, heat treatment, hot assembly and other fields of metal components. |

| Tact Time | Design according to product and process requirements | |

Related Information

If you have any questions or suggestions about the product, or if you want to know more, you can contact us at any time.

If you have any questions or suggestions about the product, or if you want to know more, you can contact us at any time.

Mobile website

Our Product

Contact Us