| Adaptive inverter frequency | Adaptive inverter load | Power temperature self-regulation | High power factor control |

| Ultrasonic frequency automatic tracking range: 15-30KHZ, IGBT high-frequency frequency automatic tracking range: 30-150KHZ, SIC ultra-high frequency automatic tracking range: 200-400KHZ | After process adjustments and load changes, the power supply and load automatically match to the optimal working state | In constant power mode, the power supply automatically adjusts with changes in load. Accurate and stable temperature control is achieved through the curve setting of heating power and time | Under any load matching and 1% -100% power output, the power factor is greater than 0.95, and there is no need for a separate power compensation device |

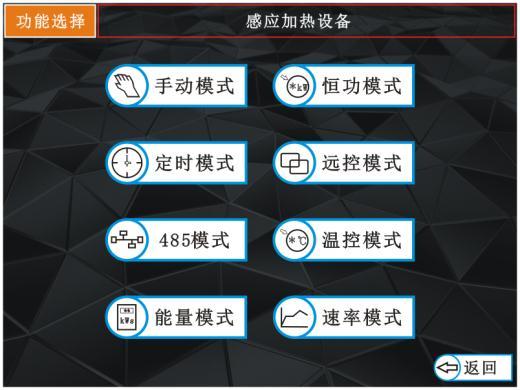

Users can modify programming or develop machining processes according to the technical requirements of the machining process. The power supply provides storage space for up to 40 sets of machining processes

The MCU processor monitors the operating status and parameters of the power supply in real-time (such as voltage, current, power, frequency, temperature, etc.), with 200 data collected per second (actual data volume), truly achieving online monitoring

Real time archiving of process data, achieving traceability application analysis, can be stored on a USB flash drive to a computer, and can be queried and analyzed using specialized software

When there is an alarm due to misoperation or special working conditions, the touch screen will display the fault content (accurately located to monitor the fault of a single IGBT). Clicking on the corresponding fault help can find the corresponding solution to the fault

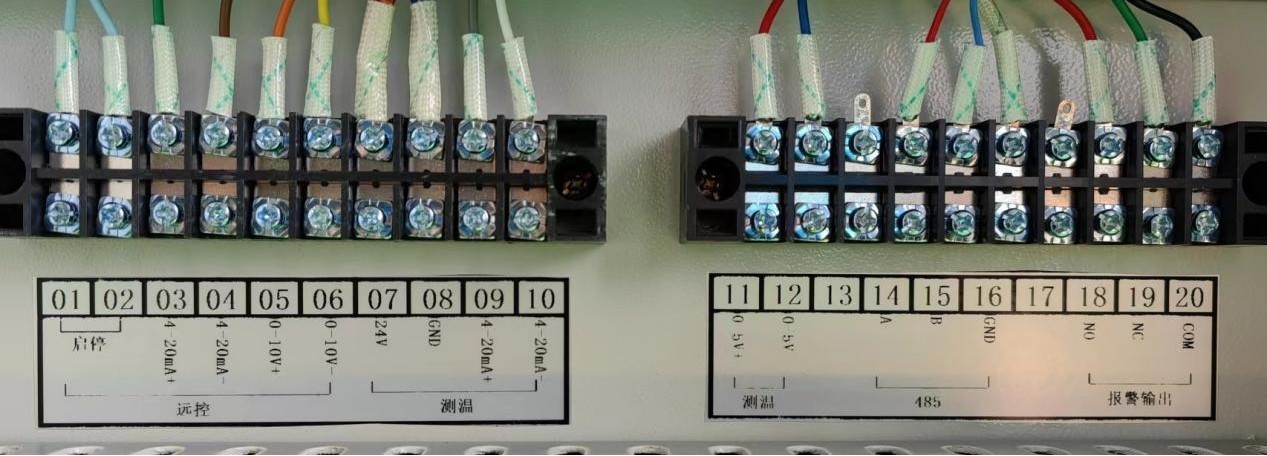

Supports classic physical buttons and remote IO operations, and power control supports 4-20MA and 0-10V analog control

Software can be used to control device start stop, power regulation, and monitor device operating parameters (such as voltage, current, power, frequency, fault information, etc.)

The communication interface supports serial port RS232485 and standard Modbus communication protocol, interfaces with industrial sites, and supports protocol customization

Implement various working modes such as timed heating, constant energy heating, curve heating, constant temperature heating, constant temperature heating, and constant power heating according to customer needs

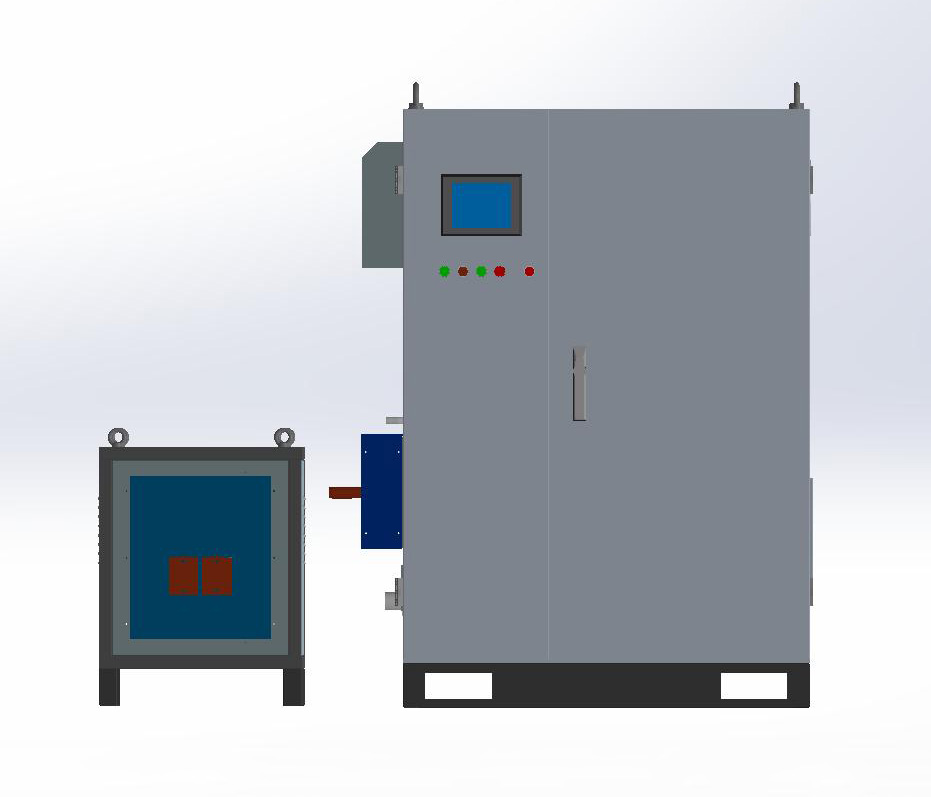

| project | model | 25 | 40 | 50 | 65 | 85 | 100 | 120 | |

| power supply | INPUT VOLTAGE | V | AC~380V±10%/Three phase three wire | ||||||

| Maximum output power | KW | 25 | 40 | 50 | 65 | 85 | 100 | 120 | |

| Maximum input current | A | 38 | 61 | 76 | 100 | 130 | 152 | 182 | |

| Copper core cable cross-sectional area | mm² | ≥16 | ≥25 | ≥25 | ≥35 | ≥50 | ≥50 | ≥70 | |

| Operating frequency range | KHz | 15-200KHz | |||||||

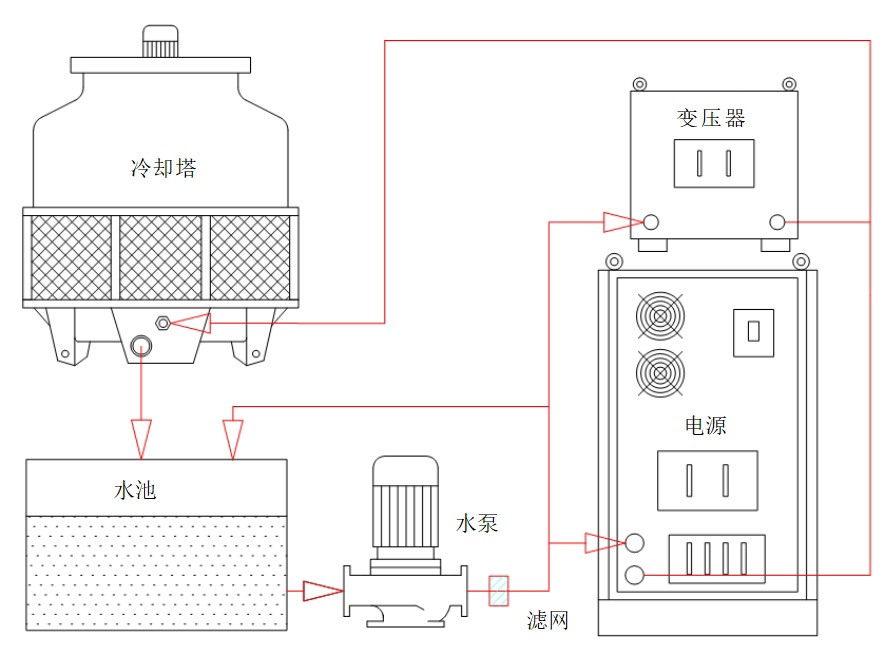

| Cooling method | Circulating water cooling | ||||||||

| cooling water pressure | Mpa | 0.1-0.2 | |||||||

| Cooling water flow rate | L/Min | 20 | 25 | 35 | 45 | 50 | 85 | 100 | |

| Suggested pump power | KW | 0.75 | 1.1 | 1.5 | |||||

| Cooling water temperature | ℃ | 10-45℃ | |||||||

| External dimensions | CM | 56*51*99 | 56*51*99 | 56*51*99 | 57*56*115 | 57*56*115 | 57*56*115 | 68*65*145 | |

| weight | KG | 70 | 70 | 75 | 100 | 110 | 120 | 185 | |

| transformer | Cooling method | Circulating water cooling | |||||||

| cooling water pressure | Mpa | 0.1-0.2 | 0.1-0.2 | 0.1-0.2 | 0.1-0.2 | 0.15-0.3 | 0.15-0.3 | 0.15-0.3 | |

| Cooling water flow rate | L/Min | 20 | 25 | 35 | 45 | 50 | 85 | 100 | |

| Cooling water temperature | ℃ | 10-45℃ | |||||||

| External dimensions | MM | 49*31*43 | 64*37*42 | 74*37*42 | |||||

| weight | KG | 35 | 40 | 65 | 70 | 75 | 85 | 90 | |

| project | model | 160 | 200 | 250 | 300 | 350 | 400 | |

| power supply | INPUT VOLTAGE | V | AC~380V±10%/Three phase three wire | |||||

| Maximum output power | KW | 160 | 200 | 250 | 300 | 350 | 400 | |

| Maximum input current | A | 243 | 304 | 380 | 456 | 532 | 608 | |

| Copper core cable cross-sectional area | mm2 | ≥95 | ≥120 | ≥120 | ≥150 | ≥185 | ≥240 | |

| Operating frequency range | KHz | 15-30KHz | ||||||

| Cooling method | Circulating water cooling | |||||||

| cooling water pressure | Mpa | 0.2-0.3 | ||||||

| Cooling water flow rate | L/Min | 120 | 150 | 160 | 200 | 230 | 270 | |

| Suggested pump power | KW | 2.2 | 3 | 4.4 | ||||

| Cooling water temperature | ℃ | 10-45℃ | ||||||

| External dimensions | CM | 68*65*145 | 80*70*177 | 120*82*162 | 120*82*162 | 150*90*202 | 150*90*202 | |

| weight | KG | 190 | 270 | 340 | 360 | 400 | 450 | |

| transformer | Cooling method | Circulating water cooling | ||||||

| Cooling water pressure | Mpa | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 | |

| Cooling water flow rate | L/Min | 120150 | 160 | 200 | 230270 | |||

| Cooling water temperature | ℃ | 10-45℃ | ||||||

| External dimensions | CM | 74*37*42 | 110*50*56 | |||||

| weight | KG | 95 | 160 | 180 | 200 | 220 | 240 | |

Prev:Fully digital induction heating equipment

Next:Fully digital ultra-high frequency induction heating equipment

Related Information

If you have any questions or suggestions about the product, or if you want to know more, you can contact us at any time.

If you have any questions or suggestions about the product, or if you want to know more, you can contact us at any time.

Mobile website

Our Product

Contact Us