The core of new energy batteries is power batteries, and the role of battery separators is also quite important. Because the positive and negative plates of the battery are separated in a small space, it is to prevent short circuits caused by contact between the two poles, but it can ensure that ions in the electrolyte can freely pass between the positive and negative electrodes. So the separator has become an important core material to ensure the safe and stable operation of lithium-ion batteries.

The electrolyte can isolate the source of combustion, the separator can increase the heat resistance temperature, and sufficient heat dissipation can lower the battery temperature, avoiding excessive heat accumulation and causing the battery to lose control. If the temperature of the battery rises sharply to 300 ℃, even if the separator does not melt or contract, the electrolyte itself will undergo a strong chemical reaction with the positive and negative electrodes, releasing gas, forming internal high pressure and exploding. Therefore, it is important to adopt a suitable heat dissipation method.

1、 Introduction to heat dissipation methods for air-cooled structures:

1. Install a cooling fan at one end of the power battery pack and leave a ventilation hole at the other end to accelerate the flow of air between the gaps of the battery cells, carrying away the high heat generated during battery cell operation.

2. Add thermal conductive silicone pads at the top and bottom of the electrode ends, allowing the heat that is not easily dissipated at both ends to be dissipated through the thermal conductive silicone pad and dissipated on the metal shell. At the same time, the high electrical insulation and puncture resistance of the thermal conductive silicone pads provide good protection for the power battery pack.

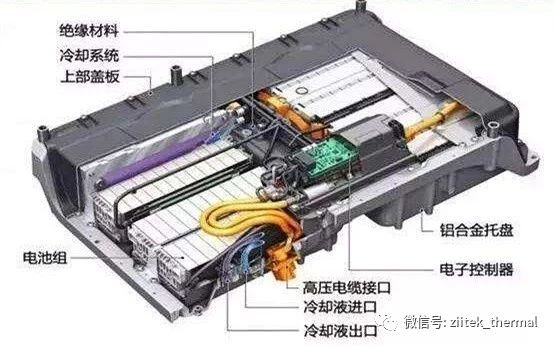

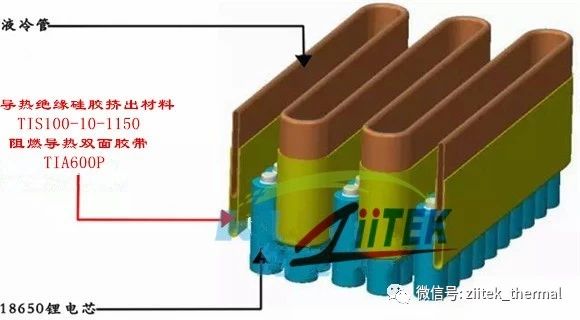

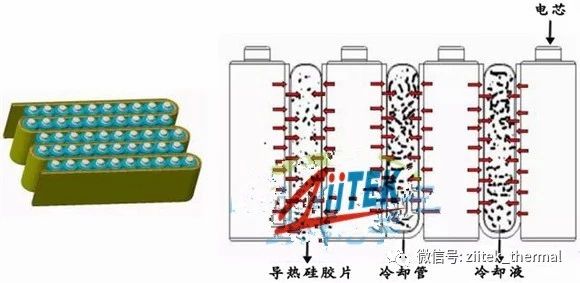

2、 Introduction to heat dissipation methods for liquid cooled structures:

1. The heat of the battery cell is transferred to the liquid cooling tube through thermal conductive silicon film, and the heat is freely circulated and carried away by the principle of thermal expansion and contraction of the coolant, which unifies the temperature of the entire power battery pack. The strong specific heat capacity of the coolant absorbs the heat generated during the operation of the battery cell, allowing the entire battery pack to operate within a safe temperature.

2. The thermal conductive silicone pad has good high resilience and insulation performance, which can effectively avoid vibration, friction, and damage between battery cells, as well as the risk of short circuits between battery cells. It is an auxiliary material for water cooling schemes.

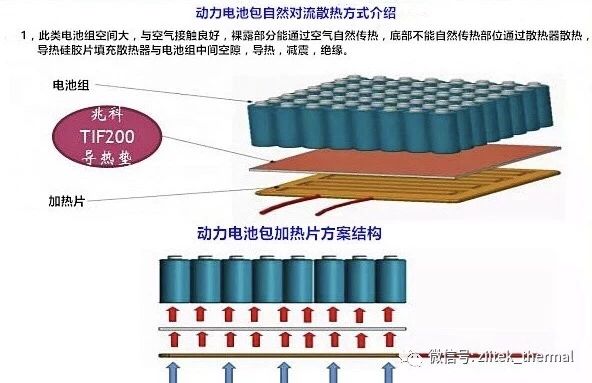

3、 Introduction to natural convection heat dissipation methods:

1. Some power battery packs have a large space and good contact with the air. The exposed parts can naturally exchange heat through the air, while the bottom parts that cannot naturally exchange heat are dissipated through the radiator. Thermal conductive silicon film fills the gap between the radiator and the power battery pack for thermal conductivity, shock absorption, and insulation.

2. The solutions in the new energy vehicle market are mostly applied to heating plates. The heat from the preheating heating element of the power battery before startup is transferred to the battery pack through a thermal conductive silicone sheet. Preheating batteries and thermal conductive silicon films have good thermal conductivity, wear resistance, and insulation performance, which can effectively heat transfer and protect against wear caused by friction between battery packs and heating plates, as well as short circuits, etc.

Popular products

News recommendations

Classification and common problems of shield tunneling tools2020-09-14

The cutting tools of shield tunneling machines can be classified according to their movement mode, arrangement position, method, and shape. According …

New type of aluminum alloy brazing material2020-09-14

The new brazing material and flux have a lower brazing temperature, which shortens the flow and filling time of the brazing material, lowers the brazi…

Brazing of aluminum and aluminum alloys2020-09-14

It should be pointed out that the process brazing performance of materials cannot be changed. With the development of brazing technology, new brazing …

Classification of brazing materials and flux2020-09-14

The main metal element in soft solder is tin, followed by lead, bismuth, zinc, gallium, antimony, cadmium, silver, copper, etc. The different combinat…

If you have any questions or suggestions about the product, or if you want to know more, you can contact us at any time.

If you have any questions or suggestions about the product, or if you want to know more, you can contact us at any time.

Mobile website

Our Product

Contact Us